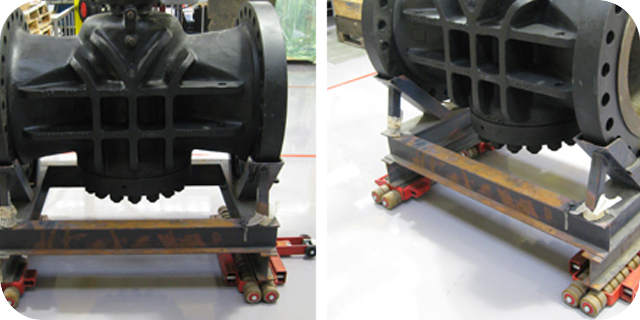

JUNG lifting jacks and machinery skates supplied by Movetech UK (the new name for British Turntable Co) are helping Flowserve Flow Control make the movement of heavy and awkward loads from the assembly line to an external despatch area safer and easier.

The 20 tonne capacity JUNG jack and the steerable trolley and rear JUNG skates, which provide a total capacity of 28 tonnes, are used to move valves for the oil & gas industry around the production floor. “These can weigh anything from 5 to 14 tonnes,” explains Flowserve’s production director Alan Watson, “and they’re not a uniform shape, either – they can have a base up to 3 metres square and 1 metre high. They have to be handled with great care, and employing the skates to do the moving has certainly streamlined the process within our strict safety criteria.

“The production line had been using a set from the maintenance department, where they have been in use for more than 10 years, but it was decided that we needed the flexibility of having our own set, which has speeded up the movement from assembly line to despatch considerably.

“Machinery skates are really the only option for moving such heavy and awkward loads. The only other alternative would be a large fork lift truck; this is not really a viable option, however, as it would be underused and requires a specially trained driver to operate.

“The JUNG jacks and skates we use are particularly robust and have an excellent reputation for longevity – as their use in our maintenance department demonstrates – and they’re very easy to use.”

JUNG heavy duty lifting and moving products are used world wide to move machinery such as large printing presses, medical scanners and machine tools. The range includes standard hydraulic jacks and machinery skates combined with a bespoke range of special transporters to fit custom loads.