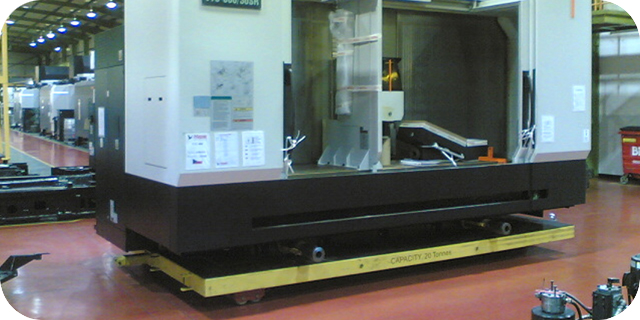

When Yamazaki Mazak of Worcester was faced with the problem of moving heavy machinery from one end of the nine loading bays to the other, Movetech UK , the new name for British Turntable, came up with a simple and cost-effective solution, designing and building a 5m x 3m 20 tonne capacity wheeled platform that is attachable to and steerable by a fork lift truck.

The problem lay in negotiating large machining equipment in one of the central bays, restricting access between the bays at either side. “The overhead crane is limited to 10 tonnes,” explains Dave Jones, shipping manager, “and we frequently need to move machine centres weighing 16 tonnes.

“One solution would have been to install tramlines in the floor, but the work would have been disruptive and, at the end of the day, very expensive. Movetech UK came up with the ideal solution – a simple wheeled transporter fitted with a tow handle at one end so that machines can be pulled manually to the right loading bay ready for dispatch.

“A further problem was the lack of space, making a U-turn of the transporter impossible. To get round this Movetech UK made it possible to lift the empty transporter with a fork lift truck and take the 300 ft return journey to the equipment loading area. It’s a simple but ingenious solution to our problems – and the most cost-effective.”

Movetech UK’s ability to provide solutions to complex materials handling and logistics problems is drawn from 50 years experience of turntable design and manufacture combined with its expertise in Hovair air film technology and JUNG heavy duty lifting and moving equipment.

Regular demands for this expertise include bespoke manual or powered solutions to present component parts to automotive process machinery, index aircraft wings or aero engines through assembly flow lines; rotate equipment undergoing testing; move large, heavy or awkward machinery into position; present components ergonomically to an operator feeding a production line; and to speed up delivery vehicle turnaround times.

In addition to an extensive standard product portfolio, Movetech UK offers a range of services which extends from pre-project advice and project design, through to delivery, installation, maintenance and calibration. Recent projects include: bespoke built 2.5m diameter turntables for cleaning buoys for Trinity House; a 100 tonne capacity air film transporter to move and store transformers round LCP’s Burntwood facility; and the supply of JUNG jacks and machinery skates to Flowserve and Hawke to move and install heavy machinery quickly and safely.

About Yamazaki Mazak

Yamazaki Mazak is the world’s largest supplier of CNC lathes, machining centres and manufacturing systems.

Mazak was the first Japanese machine tool builder to establish a manufacturing facility in Europe that handled all manufacturing operations from raw materials to finished product. The UK plant is currently the most advanced of its type in Europe, providing machine tools and sophisticated manufacturing systems to customers in more than 30 countries throughout Europe.

Yamazaki Mazak headquarters are located near Nagoya, Japan, with advanced product manufacturing facilities in Japan, USA, Europe and Singapore.